Technical Solutions Through Expertise & Partnership

- Home

- ›

- Die-Cuts & Gaskets

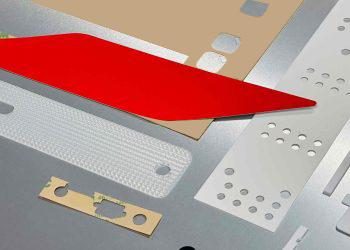

Die-Cut Components

Die-cut components are typically any unprinted material that has been fabricated into a unique shape and size. The materials can range from the simplest foams and plastics to highly engineered thermal and electrical products. Fabrication methods include die-cutting, laser, waterjet, and several other means of shaping materials into a finished part.

Application

Temperature

(High/Low/Extreme)

Extreme conditions require specialized materials

Environment

(Indoor/Outdoor)

Long-term outdoor and sunlight exposure needs specially-engineered solutions

Adhesion

(Bonding, Assembly)

Different surface properties can present bonding challenges

Chemical

(Exposure, Submersion)

Harsh chemical exposure or cleaning/sterilization processes can significantly impact material selection

How it’s used?

(Sealing, Bonding, Insulation, Shielding)

Parts need to be designed and engineered to work for and meet your specific need

Special Features of Custom Die-Cut Components

- Reduce friction between components

- Provide shielding, insulation, and thermal solutions

- Materials to prevent ingress protection from dust, dirt, and moisture

- Noise and vibration-dampening solutions

- Materials for fire and safety requirements

More Information