Technical Solutions Through Expertise & Partnership

- Home

- ›

- Access Control & Payment Systems

Custom Components for Access Control & Payment Systems

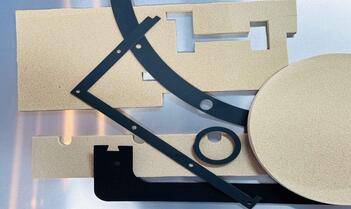

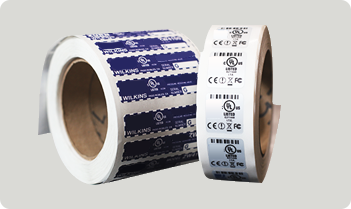

Aggressive adhesives and strong materials eliminate vandalism and break-in issues in places where monetary and security are critical. Additionally, UL94 flammability-rated and thermal-resistant materials are essential to mitigate the risk of arson or accidental electrical fires in remotely operated machines.

Melrose Solutions

- UV and UL94-resistant gaskets, insulators, heat shields, and fascia materials

- Chemically hardened cover glass displays

- UL969 compliant labels

- Reflective vinyl labels and signs for greater visibility at night

- Value-added assembly of foam, plastic & circuit layers