Technical Solutions Through Expertise & Partnership

- Home

- ›

- Industrial Nameplates

Industrial Nameplates

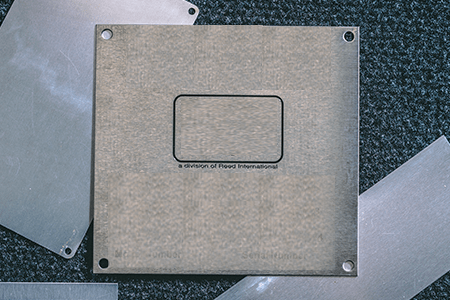

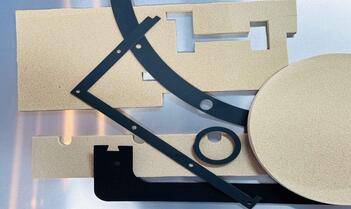

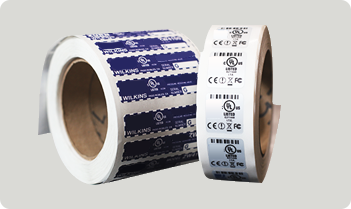

A nameplate can play an important role in establishing and reinforcing a brand identity, as well as providing crucial information. Nameplates can be made of different durable plastics and metals to provide long-term identification and branding. Customization and decorating methods can include etching, printing, engraving, or embossing to suit your preferences and brand aesthetic.

Application

Temperature

(High/Low)

Environment

(Indoor/Outdoor)

Long-term outdoor and sunlight exposure needs specially-engineered solutions

Adhesion

(Various Mounting and Bonding Solutions)

Chemical

(Designed for Exposure)

How it’s used?

(Lifecycle/User Experience. Expected lifecycle, enclosure requirements, UI experience)

Parts need to be designed and engineered to work for and meet your specific need

Special Features of Industrial Nameplates

- Can be engineered to resist abrasion, corrosion, extreme weather, and vandalism

- Customization allows for a broad range of designs and aesthetics

- Metal and plastic materials for durability

- Embossing, etching, selective finishes, and 3D visual effects

More Information